Copper or aluminum washers don't work-harden thru the relatively low pressure like they see in that application. Banging on them with a hammer, sure - squeezing them w/ a few hundred psi, no. They do 'gall' and develop small ridges/imperfections in the surface though. That's the reason for using a soft ductile metals, since they deform to match the adjacent surface irregularities and form a pressure-tight seal.

That is where a problem can arise from reusing if the surface is already deformed to the point that it doesn't adequately 'crush' again and fails to seal.

I agree that they're so cheap that it's easiest/best to just use new ones. But in a situation where I don't have new ones handy, I simply rub both sides on a piece of fine sandpaper (press w/ a fingertip & make figure-8s) and presto! - nice fresh sealing surfaces which I'd trust every bit as much as a brand-new washer.

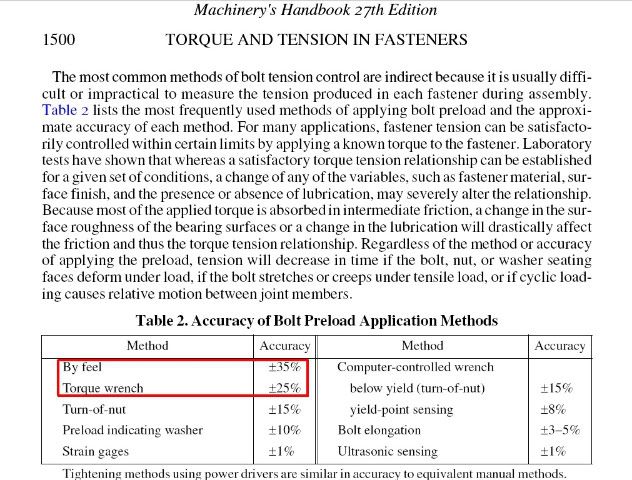

As far as torque-wrench use goes, I think lots of guys get carried away with the notion that it's the only way to achieve 'proper torque' and that not using one is just 'wrong' (hate to stereotype, but the BMW crowd seems to have lots of these overly-anal-but-don't-really-know-WTF-they're-talking-about types - not talking about you, JoshuaTree, but a 'spect you know what I mean

). With gorilla-armed wrench-turners though, using one is a good idea - it would be more appropriate to call it an 'anti-overtorque' wrench in many cases.

In many/most applications, I trust my feel/turn-of-nut method at least as much if not

more than a torque wrench.